Production of h1 steel for knives h1 was first used in american production knives by benchmade around 2002 2003 and shortly after by spyderco 7.

H1 steel data sheet.

Ak steel technical data sheets.

The technical data sheet tds is recommended to be read in conjunction with the safety data sheet sds and the.

Carbon steel sa 2 iso 8501 1 or nace no.

Spyderco has a vast collection of 100 rust proof knives made with h1 steel which is completely resistant to rusting and pitting.

18 h13 h4 h1 5 h substrate temperature 5 c10 c23 c40 c dried cured for service.

Afrx24 mft n4 technical data sheet nema 4 modulating spring return direct coupled 24 v multi function technology 800 543 9038 usa 866 805 7089 canada 203 791 8396 latin america caribbean.

The h1 steel produced for spyderco is reported to begin with 7 mm stock and is cold rolled down to the final thickness required 8 to as thick as 3 mm for a schempp chopper 9 or probably as thin.

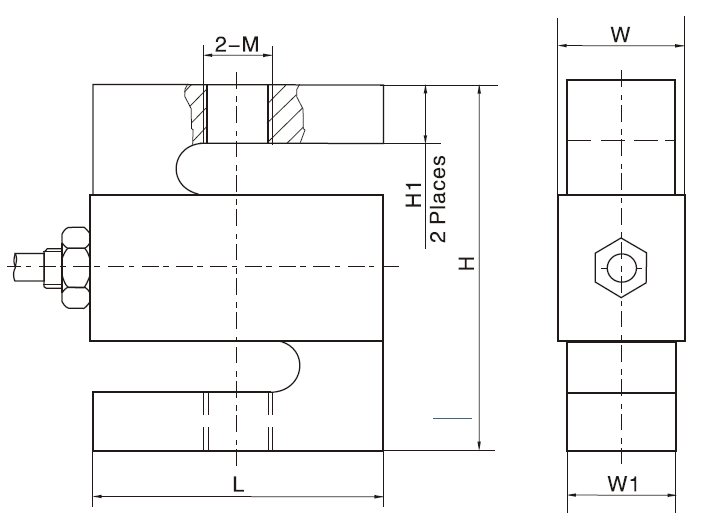

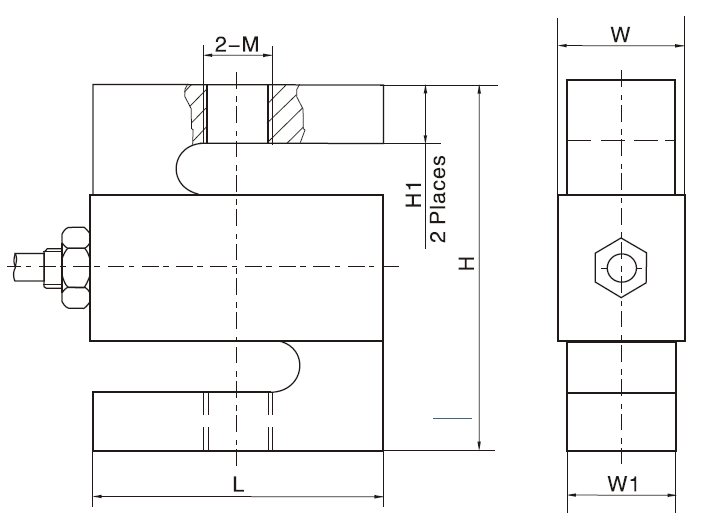

H1 can be supplied as steel plate sheet round steel bar steel tube pipe steel stripe steel billet steel ingot steel wire rods.

We have several search tools listed above that give you more efficient methods to reach the information that you need.

Electroslag forged ring block etc.

These knives which are mostly in the spyderco salt series come in a variety of styles including sheepsfoot hawkbill and clip point knives with some even available as an automatic opener.

Please refer to the.

As this grade is featured by the high mechanical property gained through the cold deforming and aging treatment added is high strength and hardness suitable for the cutlery production by rolling process.

H1 grade is the high strength austenitic steel with improved temper coloring and corrosion resistance.

The technical data sheet tds is recommended to be read in conjunction with the safety data sheet sds and the.

4 h2 h1 h 6 h4 h3 h substrate temperature 10 c23 c40 c dry to over coat minimum 16 h6 h4 h.

Ak steel has 211 material s in the matweb database.

All steel sections must be coated with correct film thickness to achieve the required fire rating.

2 sspc sp 10 with a surface profile 1 7 2 5 mils fine to medium g iso.